Extend the life of your asset

Corrosion resistant coating

Patented cold spray technology

Corrosion repair and protection

Learn More

Let Us Know How We Can Help

To learn about our services or to contact us for a quote, please fill in the form below.

Corrosion Control & Coating Solutions

In-situ corrosion control coatings and solutions – ONtech comes to you!

The ONtech Rapid Coatings Process

Our process is completed in a few short steps

-

1

Surface Preparation

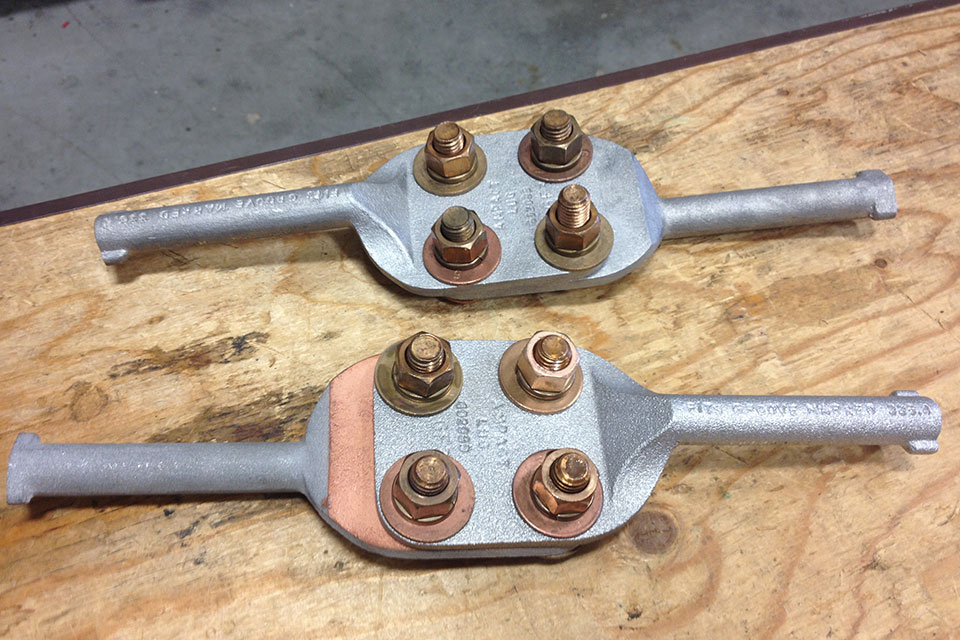

Rusted and corroded areas are surfaced prepared by grinding or sand blasting, and areas with through holes are replaced with mechanically fastened patches.

-

2

Surface Treatment

Surface preparation activities are followed by a cold spray coating or high zinc paint, as may be required, to the rusted, corroded, and other corrosion prone areas, followed by a light sanding and application of a high-quality prime paint to the entire asset.

-

3

Surface Finish

A high quality prime and finish coats of paint are applied matching the asset specification, and all asset decals are reinstated.

Partners